The Parts of a Tire

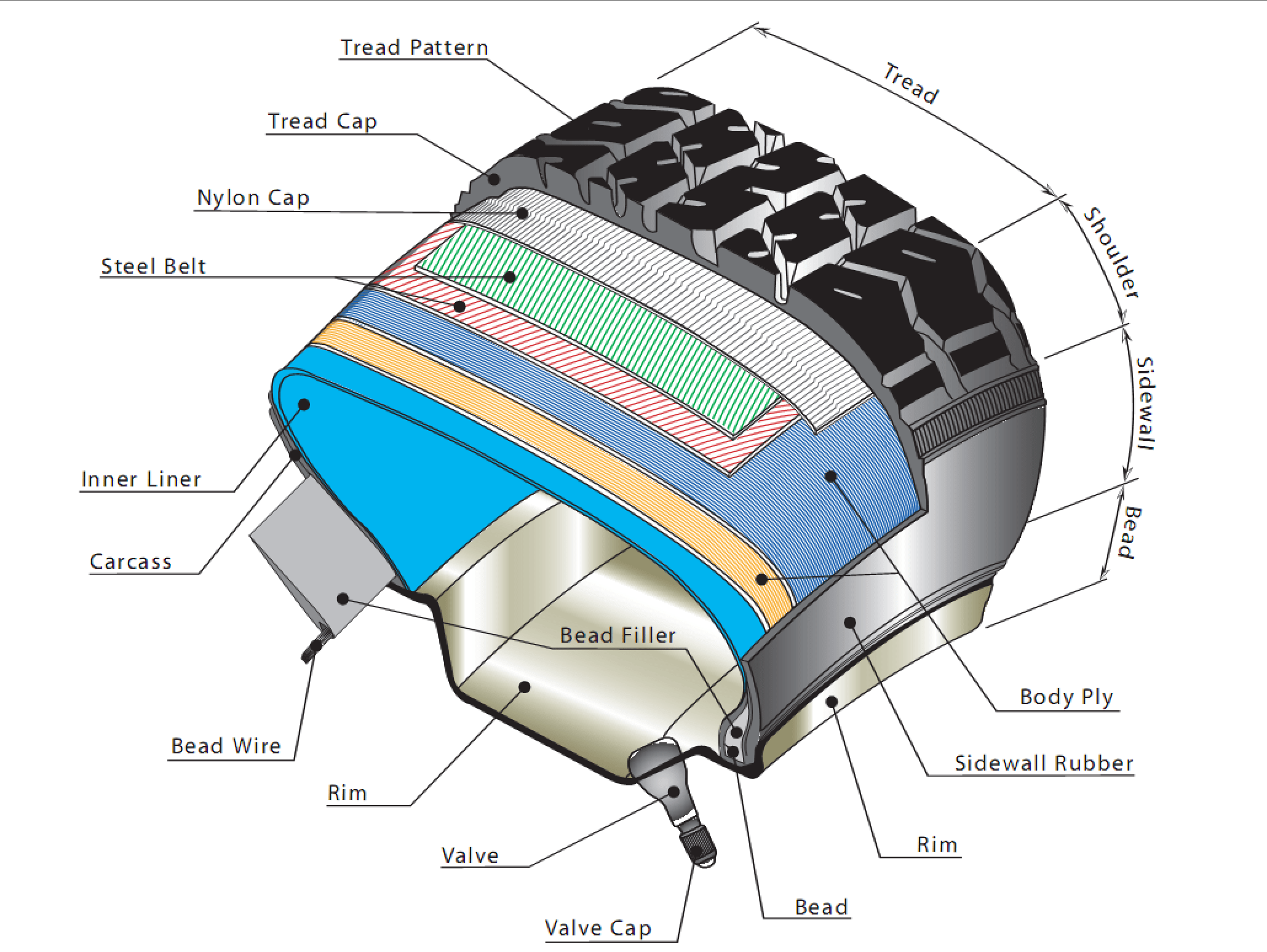

Beads

The beads are made from high-strength steel coated in rubber, and create an airtight seal between your tyre and the rim of the wheel.

Belt

Steel belts are placed around the tyre to reinforce strength and provide rigidity. These are made of woven sheets of steel wires that are coated in rubber. Sometimes Kevlar cord is also added for extra strength, puncture resistance, and durability.

Ply

The plies are the layers of fabric that make up your tyre’s skeleton, and are typically made of fibre cord that are woven together and coated with rubber. These allow your tyre to be flexible. A layer called the carcass ply is placed directly above the inner liner of the tyre and is what gives your tyre strength.

Sidewall

This is the area of extra-thick rubber that runs from the bead to the tread and gives your tyre its lateral stability. It’s also where you’ll find all the manufacturer information about your tyre.

Sipe and Groove

The tread blocks are separated by the deep grooves that allow your tyre to disperse water, snow and mud. Sipes are the smaller grooves or cuts made in the tread blocks themselves that give extra grip, which is especially important in a tyre made for snow and ice.

Shoulder

Your tyre has a small bevelled edge where the tread meets the sidewall. Its design and construction plays an important role in how your tyre helps you take corners.

Tread

This is the area of your tyre where the rubber meets the road. The tread provides both cushioning and grip, and its design and compound determine many of your tyre’s most important performance features.

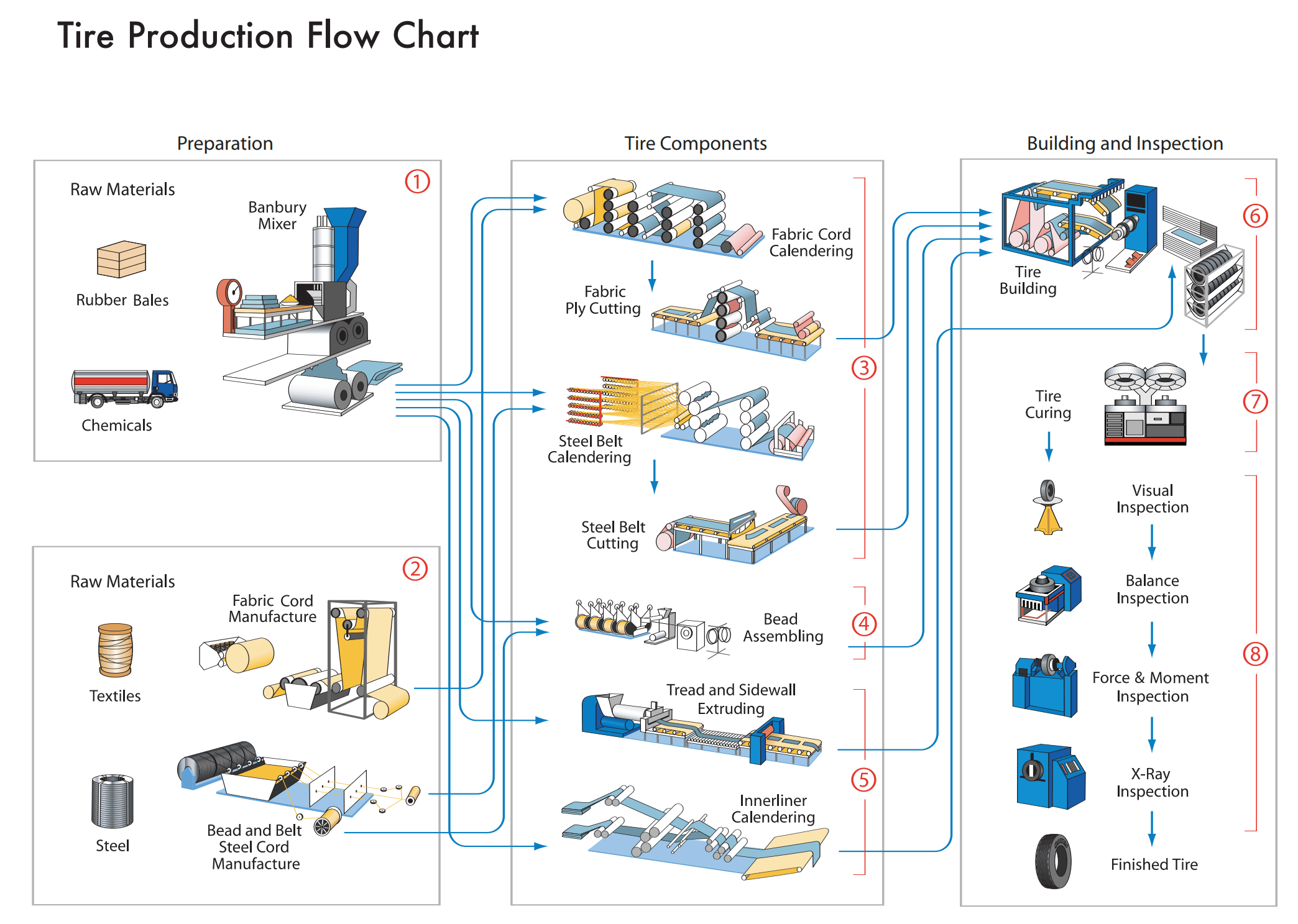

The Process of Making a Tire

Over 200 ingredients go into a tire. They play vital roles in safety, fuel efficiency, performance and eco-friendliness.

These components fall into five groups:

》Natural rubber: the main component of the tread layers

》Synthetic rubber: part of the treads of car, van and 4×4 tires

》Carbon black and silica: used as a reinforcing agent to improve durability

》Metallic and textile reinforcement cables: the “skeleton” of the tire, forming the geometric shape and providing rigidity.

》Numerous chemical agents: for unique properties like low rolling resistance or ultra-high grip