| Term | Definition |

|---|---|

| A brands |

In tire industry, A brand usually refers to 3 top world brands, MICHELIN, GOODYEAR, BRIDGESTONE, also mentioned as premium brands. |

| Air Pressure |

The amount of air inside the tire pressing outward on each square inch of tire, which is expressed in pounds per square inch (psi) or kiloPascals (kPa), the metric designation for air pressure. |

| Alignment |

When all wheels on the vehicle are adjusted so that they are pointed in the optimum direction relative to the road and each other. |

| All-season tires |

Tires that provide a good balance of traction in moderate rain or light to moderate snow with good tread life and a comfortable, quiet ride. |

| Aspect Ratio |

The relationship of a tire’s sidewall height to its section width. |

| Asymmetrical Tread Design (AD) |

Different tread patterns featured on either side of the tread that enhance and optimize performance for both wet and dry handling. The inside shoulder has more grooves for water evacuation and massive tread blocks on the outside shoulder make for maximum handling. |

| Term | Definition |

|---|---|

| Balance/Imbalance |

The state in which a tire and wheel spin with all their weight distributed equally. To correct an imbalance, a trained mechanic will add weights on the interior or exterior of the wheel. |

| Bead |

The section of the tire that sits on the wheel. Inside, there is a round hoop of steel wires, wrapped or reinforced by body ply cords, that clamps the tire firmly against the wheel rim. |

| Beads |

The beads are made from high-strength steel coated in rubber, and create an airtight seal between your tyre and the rim of the wheel. |

| Belt |

A rubber-coated layer of cords that is located between the body plies and the tread. Cords are most commonly made from steel but may also be made from fiberglass, rayon, nylon, polyester or other fabrics. |

| Belt |

Steel belts are placed around the tyre to reinforce strength and provide rigidity. These are made of woven sheets of steel wires that are coated in rubber. Sometimes Kevlar cord is also added for extra strength, puncture resistance, and durability. |

| Bias-Ply |

A type of tire with crossed layers of ply cord running diagonally to the center line of the tread. |

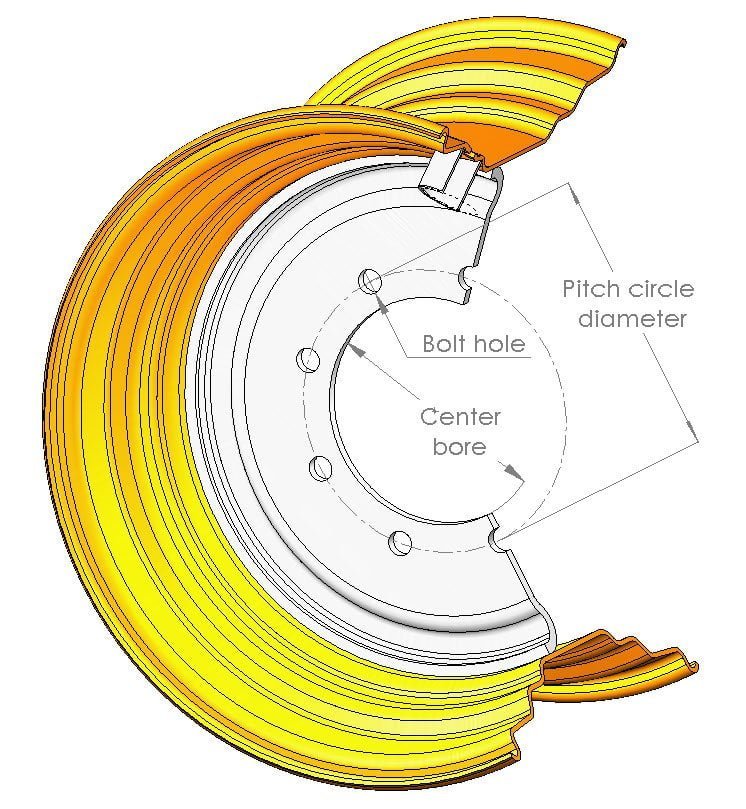

| Bolt Circle ( PCD) |

The diameter of an imaginary circle drawn through the center of each lug nut hole and then measured from two holes that are directly across from each other. The measurement is used in selecting the proper wheel for replacement.  |

| Braking Torque |

A technique practiced by drag racers and road testers to improve their off-the-line acceleration; applying the brake and throttle at the same time, increasing the engine rpm until release of the brake. |

| Butyl Rubber |

Synthetic rubber used to create today’s tires. It is virtually impenetrable to water and air. |

| Term | Definition |

|---|---|

| Carbon Black |

This is a reinforcing filler which, when incorporated into the tire rubber compound, gives it a high resistance to wear. |

| Carrying Capacity |

At a given air pressure, how much weight each tire is designed to carry. For each tire size, there is a load inflation table to ensure the inflation pressure used is sufficient for the vehicle axle load. |

| Casing |

The supporting structure of the tire consisting of plies anchored to the bead on one side and running in a radius to the other side and anchoring to the bead. Also called casing. |

| Casing Ply |

Made up of thin textile fiber cables bonded into the rubber. These cables are largely responsible for determining the strength of the tire. |

| Centerline |

An imaginary line down the center of the vehicle. Alignment tracking is measured from this line. |

| Cold Inflation Pressure |

The amount of air pressure in a tire, measured in pounds per square inch (psi) before a tire has built up heat from driving. |

| Cord |

The strands of fabric forming the plies or layers of the tire. Cords may be made from polyester, rayon, nylon, fiberglass or steel. |

| Term | Definition |

|---|---|

| Deflection |

The tread and sidewall flexing where the tread comes into contact with the road due to the load on the tire. |

| Directional Stability |

The ability of a vehicle to be driven safely and with confidence in a straight line and at high speed without being affected by pavement irregularities, crosswinds, aerodynamic lifting forces, or other external influences. |

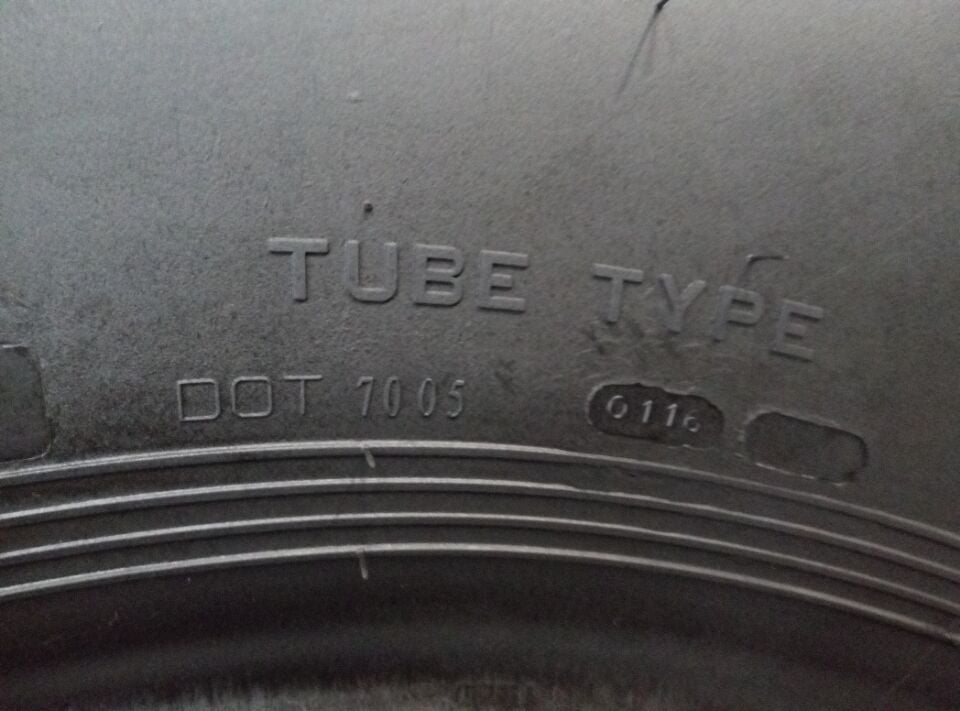

| DOT |

A molded marking into the sidewall of a tire signifying that the tire complies with U.S. Department of Transportation motor vehicle safety standards.  |

| Duals |

Tires placed side by side on an axle to increase both carrying capacity and traction capability; four tire across an axle, usually on a pickup truck. |

| Dynamic Balance |

Exists when the weight is equally distributed both around its circumference and on either side of its centerline. A tire and wheels assembly that is out of dynamic balance will produce a wobble effect or a shaking from side to side. |

| Term | Definition |

|---|---|

| Eccentric Mounting |

Mounting of a tire wheel assembly in such a way that the center of rotation for the assembly is not aligned with the center of rotation for the vehicle’s hub. |

| ECE Symbol |

The Economic Commission of Europe develops motor vehicle requirements. ECE-approved tires must meet standards for physical dimensions, branding requirements and high-speed endurance regulations.  |

| Extra Load |

Tires that are rated to carry a higher load by virtue of having a maximum inflation pressure higher than the standard maximum. |

| Term | Definition |

|---|---|

| Groove |

The space between two adjacent tread ribs; also called tread grooves. |

| Term | Definition |

|---|---|

| High-performance tires |

Also called maximum performance, ultra-high-performance, etc., offer a superior degree of handling, grip, and cornering ability than standard tires. High-performance tires are also rated for operation at higher speeds than non-high-performance tires. |

| Highway tires |

Also called summer tires; designed for wet-and-dry weather driving, but not for use on snow and ice. |

| Hub-centric |

Wheels are manufactured to fit either the hub or the lugs. Hub-centric wheels match the hub hole of a custom wheel perfectly to the diameter of the hub of the vehicle. |

| Term | Definition |

|---|---|

| Inflation |

The act of putting air into tires. |

| Inner liner |

The innermost layer of a tubeless tire, compounded with virtually impermeable butyl rubber. Some air loss over time will occur. Check your pressures monthly to ensure safe reliable operation of your tires. |

| Term | Definition |

|---|---|

| Kilopascal (kPa) |

The metric unit for air pressure. One psi is equal to 6.9 kPa. |

| Term | Definition |

|---|---|

| Light truck |

Automotive industry term for smaller trucks, pickups, passenger vans, CUV’s or SUVs. |

| Load index |

An assigned number ranging from 0 to 279 that corresponds to the load-carrying capacity of a tire. |

| Load range |

Defines a range of maximum loads that tires can carry at a defined pressure. |

| Load-carrying capacity |

Indicates how much weight a tire is certified to carry at maximum inflation pressure. |

| Loaded radius |

The measurement in inches from the wheel axle centerline to the ground when the tire is properly inflated for the load. |

| Loaded section height |

The height of the section of the tire that is making contact with the road. |

| Lug-centric |

Wheels are manufactured to fit either the hub or the lugs. Lug-centric is matching the lug holes of a custom wheel perfectly to the lug pattern of the vehicle. |

| Term | Definition |

|---|---|

| M+S, M/S or M & S |

All-season rating designation for tires that can perform at certain levels in mud and snow conditions. Meets the Rubber Manufacturers Association (RMA) definition of a mud and snow tire. |

| Maximum inflation pressure |

The maximum air pressure to which a cold tire may be inflated; can be found molded onto the sidewall. |

| Metric tire size system |

One system used to describe a tire’s size. It is the standard system of the ETRTO (European Tire and Rim Technical Organization). |

| Misalignment |

The result of your vehicle’s front and/or rear suspension not being properly aligned. |

| Mounting |

This is the act of putting a tire on a wheel and ensuring that the assembly is balanced. When you purchase new tires, they need to be professionally mounted. It is also standard for the tire dealer to charge a nominal fee for a valve stem. |

| MSRP |

Manufacturer’s Suggested Retail Price. |

| Term | Definition |

|---|---|

| Negative offset |

When the wheel mounting face is closer to the brake side of the wheel, moving the tire and wheel assembly out of the fender well. |

| NHTSA |

National Highway Traffic Safety Administration. https://www.nhtsa.gov |

| Nominal Rim Diameter |

The diameter of a tire rim, given in nearest whole numbers (e.g. 15 in.). |

| Term | Definition |

|---|---|

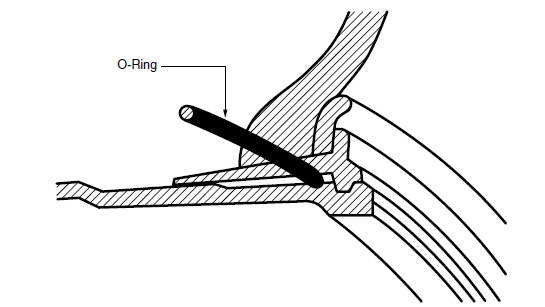

| O-ring |

O-ring is also referred to as a “seal ring”. O-ring forms an air-tight seal between separate parts of the rim.  |

| Offset |

The offset of the rim is what locates the tire/wheel assembly in relation to the suspension. A wheel with zero offset has a mounting face that directly aligns to the wheel’s centerline. |

| Original Equipment |

Tires selected by a vehicle manufacturer that best match tire performance to vehicle performance characteristics. Also known as OE. |

| OTR =Off the road |

Tires not used for highway service, usually low speed. It is a general term, it could refer to tires used in mining sites, port, agricultural field, for loaders earthmovers, forklifts etc. TNR offers the most comprehensive range of OTR tires. |

| Overall diameter |

The diameter of the inflated tire, without any load. |

| Overall width |

The distance between the outside of the two sidewalls, including lettering and designs. |

| Overinflation |

Too much air in the tire, resulting in premature wear in the center of the tread. |

| Term | Definition |

|---|---|

| P-metric |

Uniform designation of tire sizes, in metric measurements originally introduced by American tire manufacturers in 1975; commonly called P-metric series. A typical P-metric tire is P205/70R14 93S. |

| Ply |

A rubber-coated layer of fabric containing cords that run parallel to each other and make up the structure of a tire. Layers of this material are called plies, and they extend from bead to bead, between the inner liner, and belts or tread. Plies are usually reinforced with either textile or steel cords. |

| Ply |

The plies are the layers of fabric that make up your tyre’s skeleton, and are typically made of fibre cord that are woven together and coated with rubber. These allow your tyre to be flexible. A layer called the carcass ply is placed directly above the inner liner of the tyre and is what gives your tyre strength. |

| Pneumatic tire |

A tire designed to be filled with air or foam. Contrary to pneumatic, it is solid tire which no air is filled into the tire. |

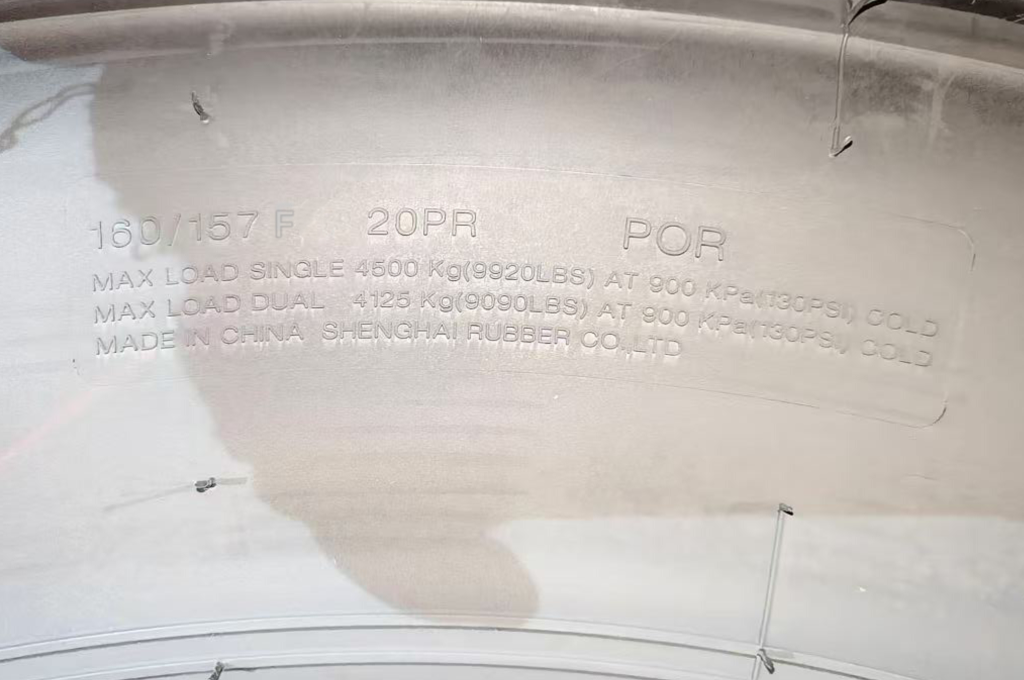

| POR |

POR, short for Professional Off-Road, are tyres specially engineered for rugged terrains like mud, sand, rocks and snow.  |

| Positive offset |

The mounting face of a wheel is toward the wheel’s street side, moving the tire and wheel assembly in toward the vehicle. |

| PSI |

Abbreviation for pounds per square inch, which is the automotive industry’s measurement of the pressure in a tire. |

| Term | Definition |

|---|---|

| Radial ply tire |

A type of tire with plies arranged so cords in the body run at 90-degree angles to the center line of the tread. |

| Ribs |

A pattern of tread features aligned around the circumference of a tire. There are usually multiple ribs across the tread area of a tire. |

| Rim |

That portion of a wheel to which a tire is mounted. |

| Rim diameter |

The diameter of the rim bead seats supporting the tire. |

| Rim Drop |

Also called drop center, a change (drop) in the rim profile between the rim flanges in which the bead area of a tire is placed during the mounting process. This allows the tire to be mounted on the rim. |

| Rim flange |

Surface of the rim of the wheel that contacts the side of the tire bead. |

| Rolling circumference |

The linear distance traveled by a tire in one revolution (its circumference). This can vary with load and inflation. Rolling circumference can be calculated as follows: 63,360 divided by revolutions per mile = rolling circumference in inches. |

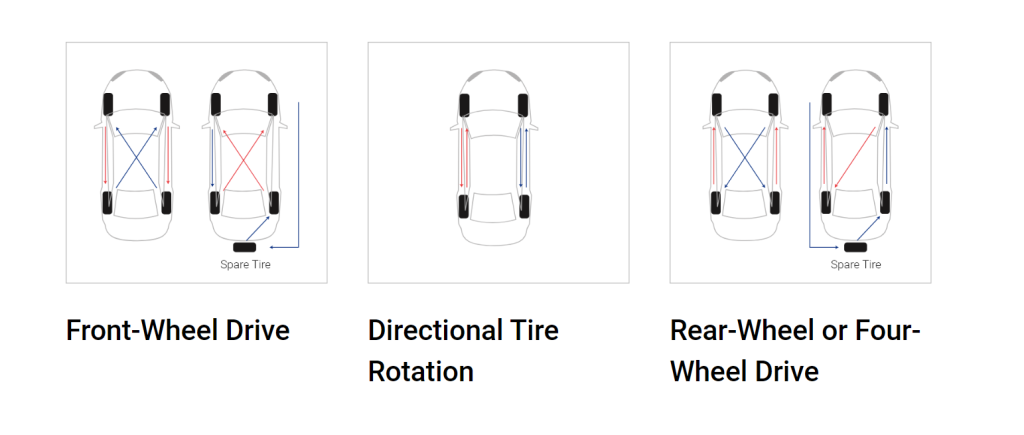

| Rotation |

The changing of tires from front to rear or from side to side on a vehicle according to a set pattern; provides even treadwear. Rotating your tires on a regular basis (every 6,000-8,000 miles) is a simple way to add miles to their life. See your tire warranty for more information on recommended rotation.  |

| Rubber compound |

A combination of raw materials blended according to carefully developed procedures. The rubber compound is specially adapted to the performance required of each type of tire. |

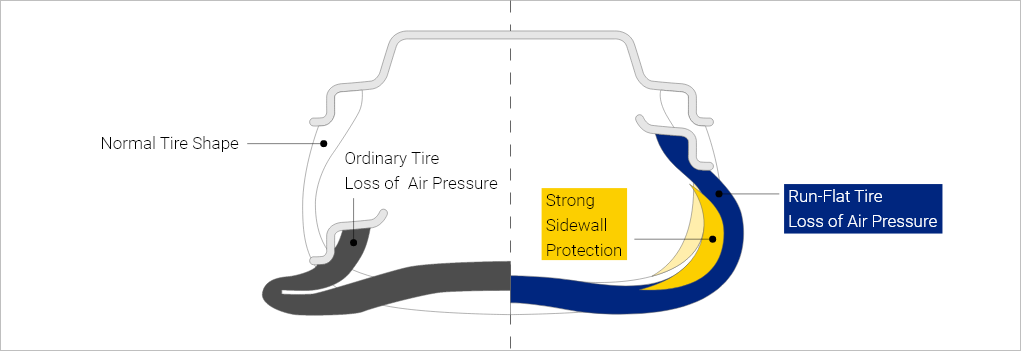

| Run Flat Technology |

Tires that are designed to resist the effects of deflation when punctured, and to enable the vehicle to continue to be driven at reduced speeds and for limited distances.  |

| Runout |

The amount a wheel moves in and out, away from its true center as it is rotated. If runout is excessive, the wheel can be seen to wobble as it rotates. |

| Term | Definition |

|---|---|

| Section height |

The height of a tire, measured from its rim to its outer tread. |

| Section width |

The distance between the outside of a tire’s sidewalls, not including any lettering or designs. |

| Self-aligning torque |

When the tire is cornering, torque created at the road contact patch acts at a point somewhat to the rear of the actual wheel center due to pneumatic trail. This has the same effect as positive caster and tends to force the wheel back to the straight-ahead position. |

| Series |

Tires with the same aspect ratio, or relationship of section height to section width. |

| Service description |

Numbers and letters molded into the sidewall indicating the load-carrying capacity, load index, and the speed at which the tire can carry a load under specified conditions, or the speed rating. Also known as load index and speed symbol. |

| Shoulder |

The area of a tire where the tread and sidewall meet. |

| Shoulder |

Your tyre has a small bevelled edge where the tread meets the sidewall. Its design and construction plays an important role in how your tyre helps you take corners. |

| Sidewall |

That portion of a tire between the tread and the bead. Protects the tire against impacts with curbs, etc. This is also where the sidewall markings can be found which tell you important information regarding the tire.  |

| Sidewall |

This is the area of extra-thick rubber that runs from the bead to the tread and gives your tyre its lateral stability. It’s also where you’ll find all the manufacturer information about your tyre. |

| Singles |

One tire mounted on each side of an axle (two tires per axle). Super Single, usually describes wide section tires like 385/65R22.5, 425/65R22.5, and 445/65R22.5. |

| Sipe and Groove |

The tread blocks are separated by the deep grooves that allow your tyre to disperse water, snow and mud. Sipes are the smaller grooves or cuts made in the tread blocks themselves that give extra grip, which is especially important in a tyre made for snow and ice. |

| Size |

The combination of tire width, construction type, aspect ratio, and rim size used in differentiating tires. |

| Snow tire |

Also called winter tire; a special type of tire with a tread pattern and compound that gives better traction in extreme snowy and icy conditions; identified by the 3 peak mountain snow flake (3PMSF) symbol on sidewall. |

| Speed rating |

An alphabetical code (A-Z) assigned to a tire indicating the range of speeds at which the tire can carry a load under specified service conditions. |

| Stability |

Situation in which the driver maintains control of the vehicle. |

| Standard load |

The amount of weight a given size tire can carry at a recommended air pressure. |

| Static balance |

Exists when the weight mass is evenly distributed around the axis of rotation. Static imbalance can be detected from vibrations through the seat, floor and steering column. |

| Static loaded radius |

Distance from the wheel axis of rotation to supporting surface at a given load and stated inflation pressure. |

| Steel belt |

The combination of steel cords covered with rubber that forms a strip or belt placed under the tread rubber and on top of the casing (carcass); ensures uniformity when the tire is rotating and helps prevent flats. |

| Structure |

The way in which a tire carcass is constructed. Radial structure tires can be identified by the word radial or by the letter R and today account for the majority of vehicle tires. |

| Suspension |

The various springs, shock absorbers and linkages used to suspend a vehicle’s frame, body, engine, and drivetrain above its wheels. |

| Symmetrical Tread Design |

Uniform tread pattern on both sides of the tread for better performance in specific conditions and on specific roads. |

| Synthetic rubber |

Man-made, as opposed to natural, rubber. Most of today’s passenger car and light truck tires have a relatively small amount of natural rubber in their content. |

| Term | Definition |

|---|---|

| Tensile Strength |

An object’s resistance to stretching or breaking when placed in tension. Steel belts in a tire are characterized and compared based on their tensile strength. |

| Tire |

Or tyre, also called pneumatic tire, a precisely engineered assembly of rubber, chemicals, fabric, and metal, designed to provide traction, cushion road shock and carry a load under varying conditions. |

| TL= Tubeless |

Tubeless tires needs no tube when mounting to a rim. |

| TRA |

Tire and Rim Association. http://us-tra.org/ |

| Track |

The distance between the outside tread edges of two tires on the same axle. |

| Traction |

The friction between the tires and the road surface; the amount of grip provided. |

| Tread |

That portion of a tire that comes into contact with the road. It is distinguished by the design of its ribs and grooves. Provides traction in a variety of conditions, withstands high forces, and resists wear, abrasion, and heat. |

| Tread |

This is the area of your tyre where the rubber meets the road. The tread provides both cushioning and grip, and its design and compound determine many of your tyre’s most important performance features. |

| Tread Buffing |

Scraping rubber off the tread. Also known as shaving. |

| Tread Depth |

The depth of usable tread rubber measured in 32nds of an inch. If a tire comes new with 10/32nds of rubber, you have 8/32nds of usable rubber. Tire must be replaced when the wear bars are visible at 2/32nds. |

| Tread Life |

The life of a tire before it is pulled from service; mileage. |

| Tread Rib |

The tread section that runs around the circumference of the tire separated by the tread grooves. |

| Tread Width |

The width of a tire’s tread. |

| Treadwear Indicator (TWI) |

Narrow bands, sometimes called wear bars, that appear across the tread of the tire when only 2/32 inch of tread remains.   |

| TT= Tube Type/Tire with Tube |

It refers to a type of tires needing a tube when mounting to a rim. |

| Term | Definition |

|---|---|

| Underinflation |

Operating a tire without sufficient air pressure to support the weight of the vehicle with occupants and additional load; could cause failure of the tire when heat is generated inside the tire to the point of degeneration of components. |

| Uni-Directional Tread |

Also known as directional tread, this is a tire designed to only rotate in one direction. |

| UTQGS |

Also known as Uniform Tire Quality Grading Standards. A government-sponsored tire information system that provides consumers with ratings (from AA to C) for a tire’s traction and temperature. Treadwear is normally rated from 60 to 900. |

| Term | Definition |

|---|---|

| Valve |

A device that lets air in or out of a tire. It is fitted with a valve cap to keep out dirt and moisture, plus a valve core to prevent air from escaping. |

| Vulcanization |

The irreversible process of heating rubber under pressure to improve its strength and resilience. |

| Term | Definition |

|---|---|

| Wet traction |

Indicates how efficiently the tire disperses water to combat aquaplaning, and how well it grips wet roads in low-speed driving. |

| Wheel weights |

Small weights attached or secured to the wheel to balance the tire and wheel assembly. |

| Wheelbase |

The longitudinal distance from the center of the front wheel to the center of the rear wheel on the same side of the vehicle. |

| Term | Definition |

|---|---|

| Zero offset |

When the mounting face of the wheel directly aligns with the wheel’s centerline. |