Foam Fill Tires Introduction

PU filled tires (PU foam filled tires) advantages:

Pneumatic tires ( air filled tires ) are widely used in automobiles, trucks, airplanes and other large numbers of transportation and truck tires because of their low weight, low price and excellent shock absorption performance. However, pneumatic tires are easily punctured or go flat. According to relevant statistics, among the pneumatic tires used in the world every year, about 40% are damaged due to puncture, and about 15% are damaged due to blasting. In addition, it is inconvenient to inflate, and the slow leakage of gas causes the vehicle to slow down and the tires wear quickly, and it will increase the rolling resistance.

A flat tire not only causes a lot of inconvenience, but also cause a lot of personal injury and property loss. Therefore, tire manufacturers have been committed to developing new types of tires to reduce the loss of pneumatic tires caused by punctures, blasts or air leaks.

Solid rubber tires, in some respects, can meet the special requirements of special conditions for tires. It has the advantages of no need to inflate, no fear of puncture, strong bearing capacity, and heavy pressure deformation, convenient use and maintenance, long service life and It has many advantages such as good resilience, and it is widely used in a variety of low-speed, high-quality construction vehicles, ports and docks and other occasions with poor road conditions. However, due to its complex structure and molding process, large consumption of raw materials, high rolling resistance, and high energy consumption, its further development is restricted to a certain extent.

PU filled tire ( PU foam filled tires, or tires filled with foam, or pu tires, or form filling tires, whatever you call it) has many advantages. In many cases, it is more practical for various occasions with poor road conditions such as engineering vehicles, mining vehicles, military vehicles and ports and docks with low driving speed and large vehicle quality.

The advantages of foam filling:

- No Punctures, Zero Downtime 24-H service

- Improved Productivity, Few Product Defects

- Longer Tire Life

- Enhanced Usage Safety

- Improved Vehicle stability in overload conditions

- Superior Heat Resistance

Foam filled Tire typical applications:

- Steel Mills

- Seaports

- Quarrying

- Rental Companies

- Waste Sites

- Demolition Sites

- Glass Factories

- AWP

- Defence & Military

Instructions for use of tire-filled polyurethane materials

Material performance:

The material properties are as follows:

Hardness, Shao A: 20~40

Density, g/cm3: 0.95~1.10

Tensile strength, MPa: 0.70 ~ 1.10

Tear strength, N/mm: 5.0~10.0

Elongation at break, %: 250~450

Rebound rate, %: 35~48

Compression set, %: 3~9

Process conditions and methods of use:

Material temperature: 20~30℃

A:B=1:1

Operable time≥60minCuring time: 7d

| Component A | Component B |

Composition | Combined polyether | Isocyanate |

Appearance | Brown-black liquid | Brown-black liquid |

Viscosity,mPa·s | 500~900 | 500~900 |

Density,g/cm3 | 0.95~1.10 | 0.95~1.10 |

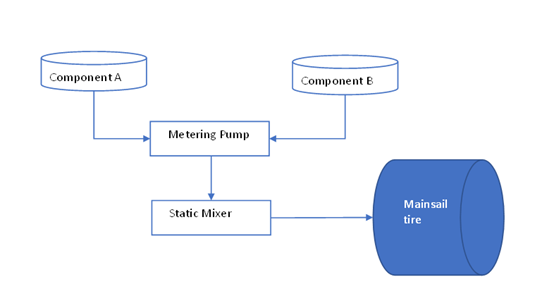

The material temperature is kept constant at 20-25°C, A:B=1:1, mixed by a metering pump and a mixer, and filled into the tire. When filling, fill the material through the tire air valve, and at the same time, exhaust through the top of the tire. When material overflows from the vent hole, stop filling, plug the vent hole, and continue overfilling. When the pressure reaches 0.6 to 0.8 MPa, the valve is closed, and the tire is cured at room temperature for one week.