Aircraft tires are tires which are designed to be used with aircraft. Aircraft tires support the weight of the aircraft while it is on the ground and provide the necessary traction for braking and stopping.

Usually, aircraft tires are classified in various ways including by: type, ply rating, whether they are tube-type or tubeless, and whether they are bias ply tires or radial tires.

There are nine types of tires, only Types I, III, VII, and VIII, also known as a Three-Part Nomenclature tires, are still in production.

Type I tires are still manufactured, but their design is no longer active. They are used on fixed gear aircraft and are designated only by their nominal overall diameter in inches. They are typically used on light aircraft with landing speeds of 160 miles per hour or less.

Type III tires are designated with a two number system. The first number is the nominal section width of the tire, and the second number is the diameter of the rim the tire is designed to mount on.

(For example: 6.50 – 10 is a tire that is 6.50 inches wide and fits on a 10 inches diameter rim)

Type VII tires are high performance tires used on jet aircraft. They are inflated to high-pressure and have exceptional high load carrying capability. Type VII aircraft tires uses a two-number system, and an X is used between the two numbers. The first number designates the nominal overall diameter of the tire, and the second number designates the section width.

(For example: 26×6.6 is a tire with 26 inches in diameter,and 6.6-inch in nominal width)

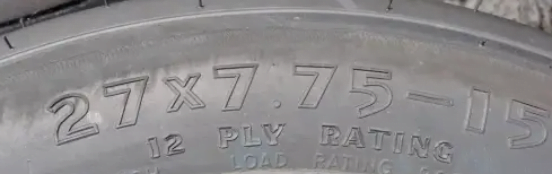

Type VIII aircraft tires are also known as three-part nomenclature tires. It is the most modern design of all tire types. They are used on high-performance jet aircraft. The three-part nomenclature is a combination of Type III and Type VII where the overall tire diameter, section width, and rim diameter are used to identify the tire. The X and “–” symbols are used in the same respective positions in the designator.

(For example: 27×7.75-15 designates a tire that is 27 inches in diameter with a 7.75-inch section width to be mounted on a 15- inch wheel rim.)

When three part nomenclature is used on a Type VIII tire, dimensions may be represented in inches or in millimeters. For example, 715×240-305 designates a Type VIII radial aircraft tire with a 715mm tire diameter, a 240mm section width to be mounted on a 305mm wheel rim.

A few special designators may also be found for aircraft tires. When a B appears before the identifier, the tire has a wheel rim to section width ratio of 60 to 70 percent with a bead taper of 15 degrees. When an H appears before the identifier(H4.54×16.5-21), the tire has a 60 to 70 percent wheel rim to section width ratio but a bead taper of only 5 degrees.

A tire ply rating is an expression of the tire’s strength and capacity. Generally speaking, a tire with a high ply rating is a tire with high strength able to carry heavy loads regardless of the actual number of plies used in its construction.

Aircraft tires can be tube-type or tubeless. The tubeless tires have no inner tube between the tire and the rim. On the other hand, a tube tire consists of an inflatable tube that holds the air in the tire.

Another means of classifying an aircraft tire is by the direction of the plies used in construction of the tire, either bias or radial. Traditional aircraft tires are bias ply tires. The angle of the plies in relation to the direction of rotation of the tire varies between 30° and 60°, they are called bias tires.

Some modern aircraft tires are radial tires. The plies in radial tires are laid at a 90° angle to the direction of rotation of the tire. Radial tires usually carry high loads with less deformation.

> Advanced material for the tire ensures excellent tire life.

> High-tech tread compound ensures excellent puncture resistance and tear resistance performance.

> Special carcass construction saves weight and creates less heat.

> Shallower tread depth helps to resist tread squirm and irregular wear forces for exceptionally long mileage.

> Special UV protection improves the tire’s ability to resist weather checking.

> Outstanding traction

> Confidence running

| Tire Size | Take off (km/h) | Landing Speed (km/h) | Rated load (KN) | Inflation pressure (kPa) | Rim diameter (mm) |

| 950×300 TL | 400 | 400 | 87.48 | 1125+49 | 466 |

| 480×200 TT | 193 | 193 | 20.58 | 640 | 151 |

| 480×200 III TT | 190 | 190 | 10 | 343+19.6 | 151 |

| 800*200 TT | 330 | 270 | 33.8 | 834±49 | 416 |

| 1050×400 TT | 230 | 220 | 55.16 | 390+50 | 369 |

| 900x300M TT | 258 | 258 | 47.07 | 490 | 368 |

| 660×200 TT | 375 | 340 | 32.86 | 1.08+0.05 | 333.5 |

| 1300×480 TT | 330 | 280 | 118.7 | 686+49 | 506.5 |

| 1100×330 | 310 | 280 | 66.71 | 735+49 | 506.5 |

| 6.50-10 10PR | 257 | 227 | 21.168 | 785+49 | 252.5 |

| 400×150 L | 195 | 195 | 4.75 | 460 | 151 |

| 1030×350 G | 360 | 300 | 161.81 | 1864+98 | 497 |

| 620×180 4A | 360 | 310 | 24.01 | 1177+49 | 303.2 |

| 1050x300M | 258 | 258 | 78.45 | 637 | 506 |

| 680×260 | 360 | 325 | 33.33 | 930±4 | 354.2 |

| 570×140 TT | 300 | 270 | 12.26 | 790+50 | 302.8 |

| 840×290 | 330 | 290 | 66.15 | 1226 | 358 |

| 840×360 | 300 | 280 | 90.25 | 1080+50 | 359 |

| 715×240-305IV | 193 | 193 | 25.68 | 470 | 305 |