In today’s fast-paced agricultural world, efficiency and sustainability are the name of the game. To meet the growing demand for food, farmers need reliable tools.

Irrigation, the process of artificially applying water to soil, is crucial, especially in areas where rainfall is unpredictable or insufficient.

‘’Irrigation scheduling is the science and/or art of applying the proper amount of water at the proper time to provide the maximum usable soil moisture in a plant’s root zone without causing harmful stress.’’

— NDSU EXTENSION

But let’s not forget—successful irrigation is about more than just moving water. Mobility and the reliability of the equipment matter just as much. Enter the irrigation tire, an unsung hero in modern farming. These tires, built to handle everything from dry fields to soggy, muddy terrain, keep mobile irrigation systems rolling smoothly, ensuring crops get the water they need, when they need it. And in agriculture, consistent water supply means better yields.

Historically, irrigation systems were either stationary or labor-intensive. However, as farms expanded, particularly in North America and Europe, the complexity of these systems grew significantly.

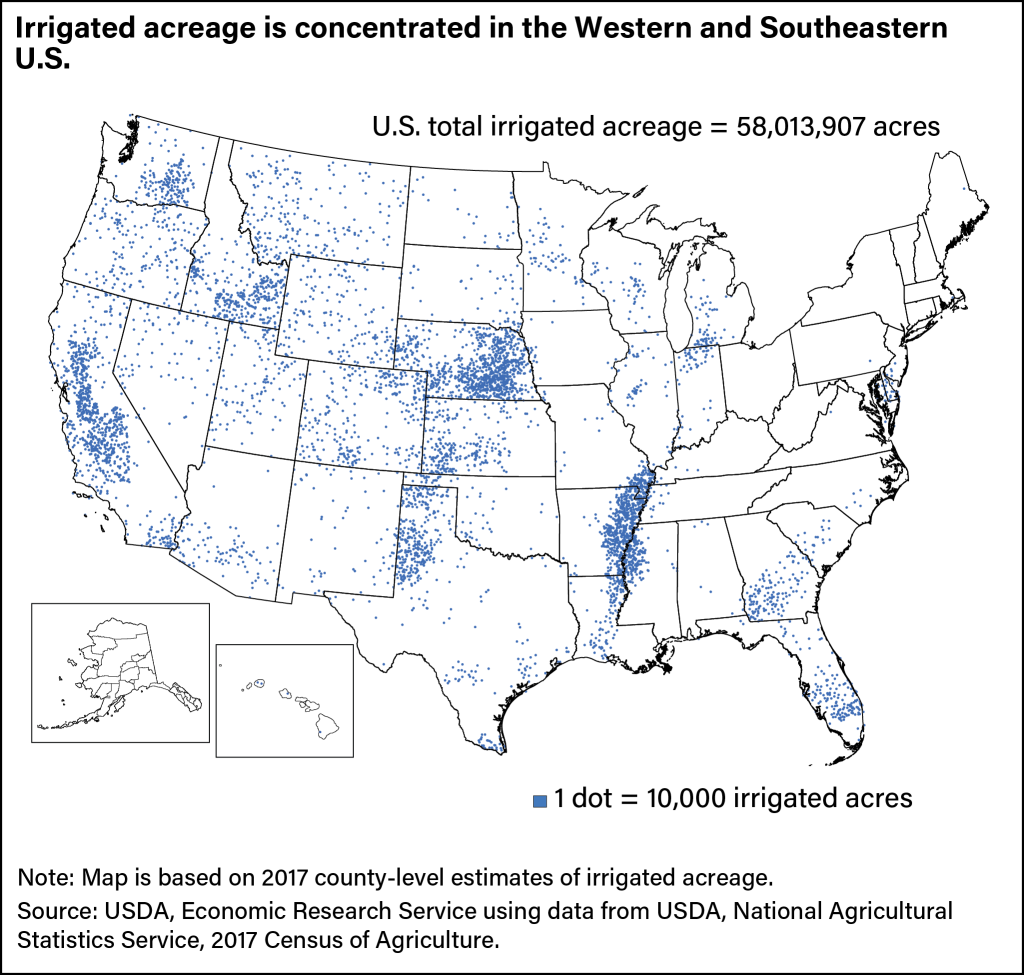

From the mid-19th century to the end of the century, the landscape of irrigation in the U.S. changed dramatically. Before 1860, large-scale irrigation projects were virtually nonexistent. Instead, small irrigation districts along rivers cumulatively irrigated no more than 1.8 million acres. During the mid-19th century, the U.S. government introduced laws and policies to encourage agricultural development in the West. This, coupled with land expansion and emigration, spurred numerous irrigation projects, marking a significant evolution in water resource development and utilization. At this time, agricultural irrigation was primarily managed by state and local governments, with most projects being privately developed. By 1890, the irrigated area in the West had expanded to over 21 million acres—more than a tenfold increase in just 20 years.

From the early 1900s to the late 1970s, the development and management of irrigated agriculture became a collaborative effort among federal, state, and local governments. The federal government increased financial investments and technical support for agricultural irrigation projects, providing preferential policies for water users. The establishment of the Federal Bureau of Reclamation, focused on constructing large-scale irrigation projects like the Hoover Dam Project and the Central Valley Project, laid a solid foundation for the West’s irrigation development. Encouraged by federal land and reclamation policies, states and private enterprises invested enthusiastically in water conservancy projects, resulting in a series of storage and large-scale cross-basin water diversion projects. By the early 1980s, the total irrigated area in the U.S. reached approximately 300 million acres, with around 267 million acres located in the West, accounting for 90% of the total.

Since the 1980s, the development of new water resources has slowed as most major water supplies have been tapped. Consequently, the growth of irrigated acreage has also decelerated. As irrigation development achieved a balance between agricultural supply and demand, the total irrigated area in the U.S. began to stabilize. Data from 2007 and 2016 indicated that the irrigated area was 399.6 million acres and 371.1 million acres, respectively, reflecting a change of less than 30 million acres over the decade.

With the decline in large-scale irrigation projects and the emergence of issues such as water shortages, environmental pollution, and drought, the focus of U.S. water conservancy shifted to effective water resource management. As a result of these challenges, agricultural irrigation increasingly emphasized technological innovation to improve water-use efficiency. Currently, the U.S. is exploring precision irrigation, establishing systems to monitor crop water needs and manage irrigation precisely to maximize benefits. Automation in irrigation management is advanced, with many irrigation districts employing control rooms for real-time scheduling and information technology.

As irrigation technology advanced, so did the ways it’s applied in U.S. agriculture. There are several different irrigation methods, each with its own way of delivering water to plants. The main goal in all methods is the same: to ensure every plant gets just the right amount of water—no more, no less—so they grow healthy and strong.

Surface irrigation, or gravity irrigation, is the oldest method, used for thousands of years. In this system, water flows over the surface of the land to soak into the soil. It works by using the natural slope of the land or gravity to carry water across fields. There are different types, such as furrow, flood, or level basin irrigation. This approach is simple and time-tested, relying on the earth’s natural forces.

Then we have micro-irrigation, which is also called localized or low-volume irrigation. This system delivers water at low pressure through a network of pipes, directing it in a controlled way to each plant. Picture it like a drip system for your garden but on a larger scale. Micro-irrigation can include systems like traditional drip irrigation, subsurface drip irrigation (SDI), micro-sprays, micro-sprinklers, or mini-bubblers, each distributing water to the plants in small, targeted amounts.

One specific form of micro-irrigation is drip irrigation, sometimes referred to as trickle irrigation. As the name suggests, water drips directly onto or near the roots of each plant, drop by drop. This is one of the most efficient irrigation methods when done correctly, since it minimizes evaporation and runoff. When well-managed, it can achieve water efficiency of about 80 to 90%, ensuring most of the water reaches the plants.

Sprinkler or overhead irrigation works by piping water to central locations in the field, where it’s sprayed over the crops using high-pressure sprinklers or guns. You might think of this system as rain on demand. Some sprinklers rotate in circles, powered by different mechanisms like gears or impacts, and are called rotors. If the system operates at even higher pressure, it uses what’s called a gun. These large sprinklers not only irrigate but are also used in industries like dust control and logging.

Sometimes, sprinklers are mounted on platforms that move around the field, connected to the water source with hoses. These systems, called traveling sprinklers, are often used on small farms or sports fields. Picture a giant hose reel that winds up while pulling the sprinkler along with it. Once it reaches the end of the field, the system shuts off automatically. This type of system is also known as a “water reel” and is commonly used for watering, dust suppression, and even spreading wastewater.

One of the most significant advancements in irrigation technology is center pivot irrigation, a form of sprinkler irrigation invented in 1940 by a farmer named Frank Zybach from Strasburg, Colorado. This system involves long sections of pipes mounted on towers with wheels. Sprinklers are spaced along the length of these pipes, and the whole system slowly rotates around a central pivot point in a large circle. This system is used worldwide and can handle all kinds of terrain. Newer versions even use drop sprinkler heads, making it easier to target the water directly onto the crops below.

Another irrigation configuration is the lateral move irrigation system, also known as linear move, wheel move, or side-roll irrigation. In these systems, water is supplied through an irrigation channel that runs along the length of the field, either positioned on one side or through the center. The motor and pump equipment are mounted on a cart that travels along this supply channel, enabling effective water distribution.

Farmers may opt for lateral move irrigation to maintain the existing rectangular shape of their fields, particularly when transitioning from traditional furrow irrigation. However, lateral move systems are less common than center pivot systems. They rely on more complex guidance technologies and require additional management, making them a more challenging choice for some farmers.

As irrigation systems evolved, so did the need for reliable equipment to support them. For example, center-pivot sprinklers, essential to U.S. dry-crop farming, rely on more than just water efficiency; they also depend on durable machinery. In particular, tires play a vital role in keeping these systems mobile and effective across various terrains. As farming needs grow, the right tires are crucial to ensure these irrigation systems continue to perform at their best.

However, the reliance on standard tractor tires in the past underscored the challenges faced by these systems. These repurposed wheels proved inadequate for navigating wet and uneven terrain, which significantly hindered the effectiveness of irrigation efforts.

For example, in the 1950s, a farmer in California attempted to use standard tractor tires for his irrigation system. When rain arrived, these tires lost traction in the muddy fields, causing the machinery to become stuck. This situation created a domino effect: because the irrigation equipment was immobilized, it could not perform its critical function of watering the crops. During this time, crops required timely irrigation, especially in their key growth stages. The delay in irrigation due to the stuck machinery meant that crops did not receive enough water when they needed it most, ultimately leading to decreased yields. This example highlights the dangers of using inappropriate tires—poor traction can result in accidents, exacerbate soil compaction, and ultimately reduce productivity.

Recognizing these challenges, the introduction of specialized irrigation tires in the mid-20th century significantly transformed agricultural practices. In the 1960s, manufacturers began to understand the need for durable, terrain-specific tires, leading to the creation of the first irrigation tire. Designed to navigate tough field conditions, especially muddy terrain, these tires allowed equipment to move efficiently while minimizing soil damage.

The first significant players in agricultural irrigation were bias irrigation tires. They’re built by layering multiple sheets of rubber-coated fabric diagonally, which gives them a stiff, strong structure perfect for tough terrains. Their resilience against damage has made them a staple in farming for decades. Most importantly, many farmers find themselves in tight financial situations before the harvest season, often unable to generate any income from their land and crops. This leaves them with limited cash to invest in upgrading to more expensive equipment, as every penny counts, and there is no guarantee that the profits from their crops will cover those costs. As a result, these tough little warriors have become the first choice for farmers, perfectly suited to tackle the toughest conditions.

In the 1980s, radial irrigation tires entered the market, introducing a range of new benefits. Their plies run perpendicular to the tread, giving them a more flexible ride. With their flexible sidewalls and better load distribution, radial tires offered improved mobility and significant fuel savings due to reduced rolling resistance. A farm in Nebraska, for instance, reported a 20% reduction in fuel consumption after making the switch to radial tires. They also provide superior traction and perform well on uneven or wet surfaces, while offering longer lifespan and lower maintenance. However, the higher upfront cost of radial tires can be a challenge for smaller farms. While large operations may find the investment worthwhile, many farmers with tighter budgets still prefer bias tires for their reliable balance of durability and cost-effectiveness.

After gaining a basic understanding of irrigation methods and irrigation tires, it’s time to dive into how to choose the right tires for your specific needs.

The first thing to consider is the type of machine you’re using, which depends on the irrigation system in place. Different irrigation systems, such as Surface Irrigation, Micro-Irrigation, Drip Irrigation, and Sprinkler Systems, require different approaches. However, irrigation tires are only necessary for two specific systems: the Center Pivot Irrigation System and the Lateral Move Irrigation System. These systems involve machines that move across the field, making tire selection a critical decision.

Pneumatic pivot tires are commonly used and are considered the industry standard. Their primary benefits are compression and flexibility, which allow them to handle obstacles with ease while reducing stress on the gearbox. However, they do have disadvantages. Flats caused by sidewall damage or punctures can result in the tire filling with mud and water, increasing the weight and potentially damaging the gearbox or the system itself. In addition, due to their convex design and directional tread, pneumatic tires often create ruts in the soil. Over time, these ruts can harm the soil and crops, ultimately reducing crop yield.

Steel pivot tires present another option, as they will never go flat. The appeal of a tire that won’t deflate can be tempting, but steel tires lack the flexibility of their pneumatic counterparts. This rigidity can strain the gearbox and lead to frequent replacements, which is something to keep in mind if you’re considering this option.

Similarly, plastic pivot tires are also immune to going flat but are not puncture-proof. If they get punctured, they can fill with water and mud, adding extra weight and creating the same risk of damage to the gearbox as steel tires. Additionally, the low flexibility of plastic tires results in poor traction, which may further increase the likelihood of gearbox damage.

Rubber pivot tires, particularly airless ones, offer a more balanced solution with better flexibility and traction compared to steel or plastic options. These tires can flex around obstacles, reducing the strain on the gearbox and providing smoother operation. Despite this, rubber tires still tend to create ruts in the soil. Their design, which allows them to dig into the ground for traction, can lead to long-term damage to the soil and crops. Over time, these ruts might also cause the tires to get stuck, raising the risk of damage to the irrigation system.

In conclusion, selecting the right tires for center pivot and lateral move irrigation systems is critical to the overall success of your irrigation operations. Each tire type comes with its own set of advantages and disadvantages, making it important to choose carefully based on your equipment’s specific needs and the conditions of your irrigation system.

Understanding your budget is a crucial step after identifying the equipment and tire type necessary for your agricultural needs. This involves a careful evaluation of how much you are willing to invest in agricultural equipment and its components, including tires.

Among the four types of tires discussed earlier, pneumatic pivot tires are predominantly utilized in farmlands today. Therefore, it is essential to explore how to select the right pneumatic tires for your pivot irrigation system.

Pneumatic pivot tires can be classified into two categories: bias and radial, which is determined by their construction. Both types are air-filled, but they differ in their internal ply structure. Bias tires are often more budget-friendly and designed to perform well in challenging terrains, making them a popular choice for many farmers. On the other hand, radial tires tend to have a longer lifespan and provide superior traction, although they typically come with a higher price tag. In fact, radial irrigation tires of the same size generally cost about 20% to 30% more than bias tires. The specific price differences can be influenced by various factors, such as brand, materials, design, and market supply and demand, which will not be discussed in detail here.

By understanding the cost implications of both bias and radial tires, you can make an informed choice that balances performance with financial feasibility.

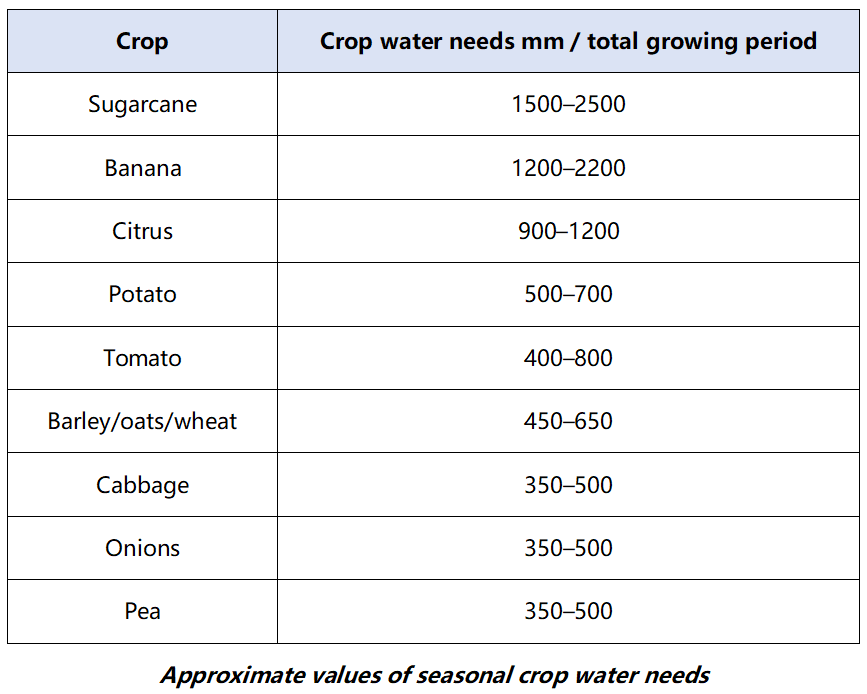

Every farmer possesses an intimate understanding of their crop, but many may not be as familiar with the suitable tire sizes essential for optimal growth. We will explore how to select the most appropriate tire sizes based on the type of crop you are cultivating. Understanding the exact tire size your crop requires is crucial for maximizing productivity and ensuring healthy growth.

Let’s begin with one of the most popular tire sizes in irrigation: the 11.2-38. This tire is a favorite for center pivot irrigation systems due to its narrow profile, which provides excellent traction while minimizing soil compaction. It glides effortlessly across large fields, making it particularly well-suited for expansive areas. The 11.2-38 tires excel with crops such as corn, wheat, soybeans, and cotton. For instance, during the critical growth stages of corn, particularly during pollination, these tires ensure even water distribution, giving the plants the best chance to thrive.

Transitioning to a slightly wider option, the 14.9-24 tire strikes a perfect balance between flotation and load capacity. This tire is ideal for lateral move irrigation systems, adept at handling both wet and dry conditions. The wider footprint of the 14.9-24 makes it particularly effective for various crops, from alfalfa to potatoes. Alfalfa crops, which require frequent irrigation, benefit significantly from these tires, as they prevent getting stuck in soggy fields, allowing for consistent water delivery.

Another versatile choice is the 11.2-24 tire, which offers an excellent combination of stability and maneuverability. These tires are popular for both small center pivots and lateral move systems, making them suitable for a wide range of terrains. They are particularly effective for crops like rice, soybeans, peanuts, and barley. In rice farming, where fields are often waterlogged, the 11.2-24 tires can navigate without compacting the soil, ensuring healthy plant growth and consistent irrigation.

Each tire size offers unique benefits tailored to specific terrain and crop requirements. By gaining a thorough understanding of your fields and their needs, you can select the perfect tire size that enhances irrigation efficiency, minimizes soil compaction, and fosters vibrant crop growth. Whether you opt for the nimble 11.2-38 for corn or the sturdy 14.9-24 for alfalfa, selecting the appropriate tire can significantly impact the success of modern farming.

Generally, there are two main tread patterns for irrigation tires: directional and bi-directional. Each serves a distinct purpose and is designed for specific conditions, allowing farmers to select the best option for their unique needs.

Directional tires are primarily designed to enhance traction and control in muddy or wet soil conditions. Their V-shaped tread patterns are specifically engineered to optimize water evacuation, significantly reducing the risk of hydroplaning while improving grip on slippery surfaces. The design features specialized channels that efficiently guide water away from the tire’s contact patch, helping to minimize water buildup. This ensures that the tire maintains traction even in challenging conditions.

In American farming, directional tires find frequent application in fields that experience heavy rainfall or extensive irrigation. For instance, corn farms in the Midwest often employ directional tires on their tractors and irrigation equipment. These tires allow machinery to navigate through wet fields without getting stuck, enabling farmers to continue their operations even after significant rainfall. The advantages of directional tires are clear: they provide enhanced traction, improved water evacuation, and better control, making them ideal for slippery conditions. However, they do have some drawbacks, such as being designed for specific rotational directions. Reversing their direction can lead to reduced performance, and they may not perform as well on dry, hard surfaces.

On the other hand, bi-directional tires are crafted for optimal performance in both forward and reverse directions. This design caters to diverse driving conditions, offering greater versatility for tire usage. Bi-directional tread patterns typically feature symmetrical grooves, ensuring consistent performance regardless of the direction of travel.

The technology behind bi-directional tires incorporates a combination of wide and narrow grooves, allowing for effective water dispersion while enhancing traction. This tread design helps maintain stability and control in a range of agricultural settings, from dry fields to muddy terrains.

These tires are particularly well-suited for farms that require a high degree of versatility in their machinery. For example, a wheat farm using a range of equipment for planting, cultivating, and harvesting can greatly benefit from bi-directional tires. These tires facilitate movement across various soil conditions, ensuring reliability throughout the farming season. The advantages of bi-directional tires include their versatility, consistent performance in different driving conditions, and durability due to reinforced sidewalls. However, they may not provide the same level of traction as directional tires in extremely muddy conditions, making them less specialized for specific scenarios.

After exploring the details about irrigation tires, you might already have a plan in mind!

Is the 11.2-38 with a directional tread the right fit for your cornfields in Iowa?

Or perhaps the 14.9-24 with a bi-directional pattern for your potato fields in Idaho?

Still unsure or need more specific guidance?

Don’t worry! Reach out to our irrigation experts NOW, and we’ll provide the support you need to make the perfect choice.